Analytical Capabilities

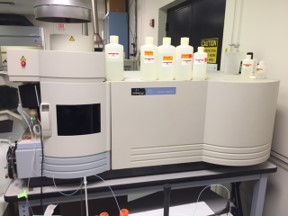

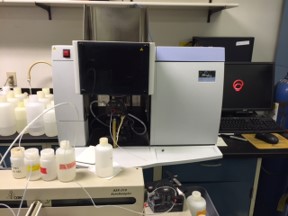

Over the years, APL has excelled in manufacturing of single/multi component metal halides. In order to support this excellence in our manufacturing processes, a state-of-the art, analytical laboratory is available on site for testing the synthesized materials at APL. This enables us to maintain our robust quality program, as well as allows us to meet the expectations of the most demanding customer.

We are constantly developing and validating new analytical procedures, as applicable to metal halides for various applications. Our analytical laboratory also serves as a space for supporting contract manufacturing operations. The technicians at APL are also trained to operate equipment at the prestigious University of Illinois, Urbana, IL in case of special analyses. Please contact us if you require analysis of inorganic materials or compounds. We have the following instruments on site:

|

ICP-MS Trace metal impurities |

ICP-OES Trace metal impurities |

|

Flame AA/AE Cs, Rb major |

pH meter pH of solutions |

|

Particle size analyzer Laser diffraction particle size analyzer |

Thermogravimetry Mass loss upon heating, phase transitions |

|

Karl Fisher titration |

O-detection |

Additional Capabilities at APL

| Technique | Capability |

| Fourier Transform Infrared Spectroscopy | Characteristic vibrational modes |

| Potentiometric titration | Cl-, Br-, I- (major) |

| BET surface area | Surface area and pore size distribution |

| UV visible spectroscopy | Absorption of solutions |

| Fluorescence spectrometer | Excitation / emission spectrum |

Routinely used equipment at University

- X-ray diffraction (single-crystal / powder)

- Scanning/transmission electron microscopy

- Cross-sectional polishing with electron beam

Glass Shop

Moisture sensitive products such as many metal halides require specialized packaging.

APLs master glassblower & apprentices work closely with engineering, research & development to design, manufacture and repair proprietary vessels which not only meet our production requirements but also are used by our customers in circumstances that require limited material handling. In such cases, APL aids in design and manufacturing of special ampoules that can be used as-is after and during product transport.

Custom Manufacturing

- APL maintains a 120,000 sq. ft. state-of–the art production & packaging facility that is operated by our experienced team of production technicians, engineers, and R&D team. It enables us to isolate your process to a specific area, with strictly limited access.

- We understand the importance of your IP and work hard to meet your timelines and budget. We have successfully completed custom manufacturing projects that range from hundred of grams to tens of thousands of kilograms in scale.

- We offer a variety of manufacturing resources and are open to adding more, as needed-

- High temperature furnaces for vacuum, inert has and reactive atmosphere solid state reactions.

- Powder processing equipment

- Gloveboxes for handling under inert atmosphere

- Wet-chemistry and sol-gel synthesis

- Packaging under inert atmosphere

- Schlenk lines for moisture-free chemistry

- Access to APL’s Analytical facility, Glass and Machine shop